The fruiting bodies of mushrooms, like the ones growing in the woods in the image below, are a delicious food that has long been consumed throughout the world. However, what many people don’t know is that the main body of the fungus grows underground in the form of a vast subterraneous fungal system with a root-like structure. This underground system – called the mycelium – is a part of all fungi, and can also be eaten. In contrast with the cultivation of the fruiting bodies that arise from fungal mycelium, the production of mycelium itself is far less complex.

Recent research has shown fungal mycelium to be a highly promising alternative-protein source. In the Smart Protein project, we make use of mushroom mycelia to convert complex substrates (the ingredient base that the mycelium feeds on) into a palatable biomass that is rich in proteins and other valuable nutrients. The production of fungal mycelium can be divided into two main fermentation techniques: solid- or liquid-state fermentation. Both approaches are pursued within the Smart Protein project, with Mogu focusing on the former and Fraunhofer IME-BR on the latter.

The use of fungi in the Smart Protein project

With liquid-state fermentation, the fungus is cultivated in an aqueous environment that contains all the nutrients necessary for its growth. In the case of the Smart Protein project, side-streams from the food industry, such as broken pasta residuals, bread crusts, lentil fibres, and pent brewer’s yeast, are used, together with pure drinking water. It is therefore a highly sustainable process.

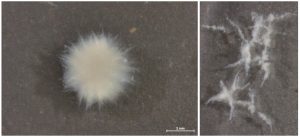

This liquid medium, which is called the culture broth, is sterilised in order to prevent the growth of any unwanted microorganisms and, after cooling to a specific temperature, is inoculated with the fungus. Depending on the species, the fungus grows in a pellet-like shape (see Fig. 2) or a filamentous form, and may colour its surrounding medium and generate different types of flavours. Interestingly, the resulting smells and flavours are not limited to the expected mushroom-like odour, but can range from fruity to floral and can even have meaty scent notes.

Fig. 2: Mycelial pellet (left) and filamentous form (right) of a fungus, grown in liquid-state fermentation. © Andreas Hammer, Fraunhofer IME

Fig. 3: Five-litre lab-scale glass bioreactor. The culture broth is grown via the presence of a fungus, which leads to the forming of a yellow-orange colourant. Multiple connections can be seen. © Andreas Hammer, Fraunhofer IME

This mycelial raw material is of high nutritional value. It is low in lipids, but contains healthy (poly)unsaturated fatty acids. It is rich in high-quality protein, contains complex carbohydrates such as beta-glucans that function as dietary fibre, and contains valuable micronutrients, including several B vitamins. With the addition of UV light, natural precursors in the fungal tissue can even be converted into vitamin D. In addition, fermentation with edible fungi not only leads to balanced nutritional profiles but, in many cases, the degradation of undesired ingredients in substrates, so called ‘anti-nutrients’, has also been reported. The resulting material can be further processed for use in other food products or used directly as food. For example, it is suitable as a meat-alternative and can also be served in the form of breaded vegan nuggets (fig. 5).